The rolling bearing needs to maintain high precision rotation while bearing more force repeatedly on the contact surface of the ring and the rolling body. The load will eventually break the surface and cause the bearing to lose Effect. To delay the appearance of material fatigue, the bearing ring and rolling material shall have the following characteristics.

High hardness, strong rolling fatigue performance, wear resistance, good dimensional stability, good mechanical strength.

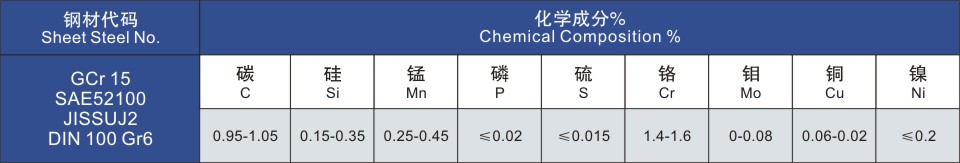

Nowadays, chromium steel is the best choice for rolling bearings and has a wide range of applications. Due to the continuous demand for bearing life continuity, the chromium steel for ball bearings is manufactured and should be Provides maximum balance with performance. This type of steel usually occurs during martensite or bainite thermal treatment and ranges in hardness from 58 HRC to 65HRC. The vacuum takes off Gas, chromium bearing steel GCr15 is a standard material for precision ring and rolling body materials, which have uniform specifications AISI52100(USA), DIN100Cr6 JISSUJ2(Japan).

Chemical composition of chromium bearing steel:

With the ability and facilities to provide a wide range of materials, processes and processes, our application engineers can assist in selecting these bearings to provide excellence for specific applications Performance.

The material of the retainer must have good wear resistance, dimensional stability, good mechanical strength and perfect adaptability to bearing operation. Therefore, for selective insurance Holding material, it is important to consider the operating environment.

Stamping plate cage

These lightweight retentors have high strength and are surface treated to reduce friction and wear.

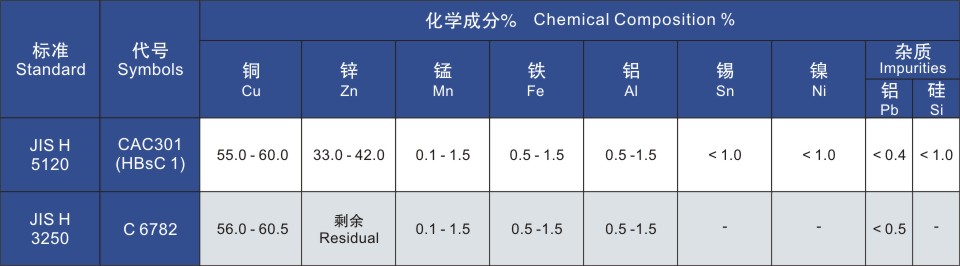

● brass cage

Small and medium sized bearings are equipped with brass cutout cage, but brass cage is not suitable for compressor using ammonia cooling, because ammonia causes seasonal fracture of brass, Therefore, steel cage should be used instead.

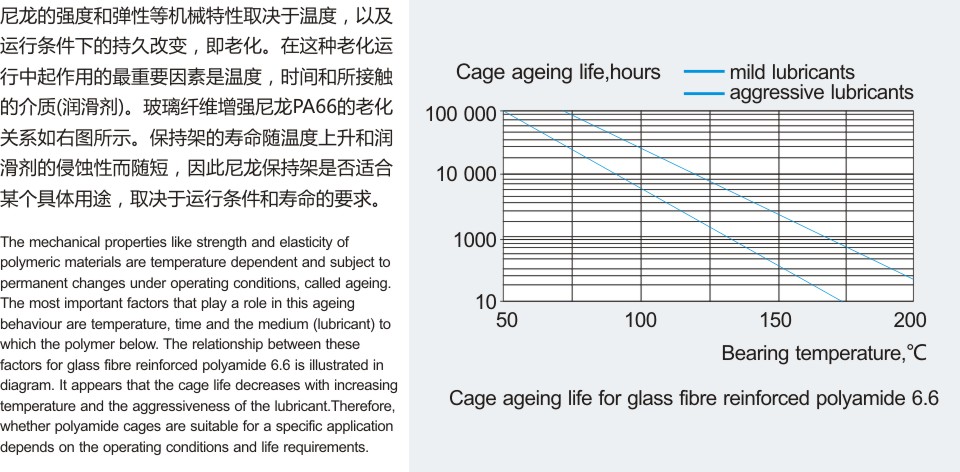

● nylon cage

According to the types and USES of bearings, nylon cage is more and more widely used, but not suitable for more than 120℃ or below 40℃ environment. Most are cast and molded The v-shaped cage is made of nylon PA66, a material with or without glass fiber reinforcement, characterized by a good combination of strength and elasticity.

● dust cover material

The standard material for the dust cover of mairui bearing is cold-rolled electroplated tin steel plate, and sometimes aisi-300 stainless steel is used.

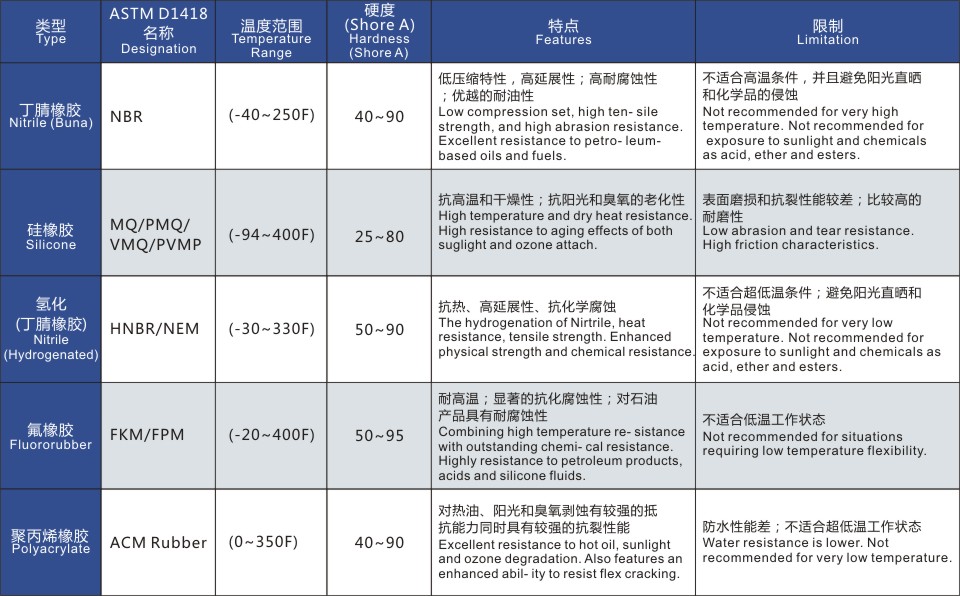

● sealing ring material

The sealing ring is mainly made of nitrile butadiene rubber, which is widely used in high temperature environment.

Fluororubber is safe and harmless under normal working conditions below 200℃, but when the temperature exceeds 300℃, which is equivalent to the fire of cutting steel tube, fluororubber will release smoke. this Some smoke is harmful when inhaled by humans, including eyes, and be careful to avoid contact with skin.

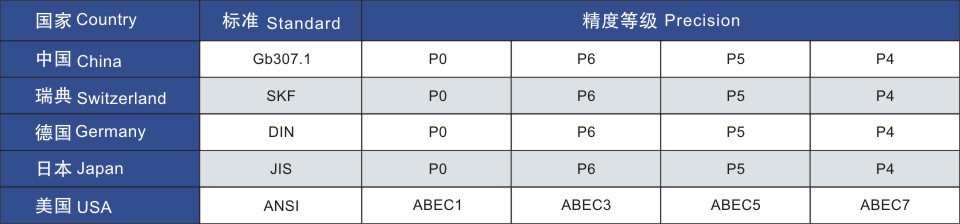

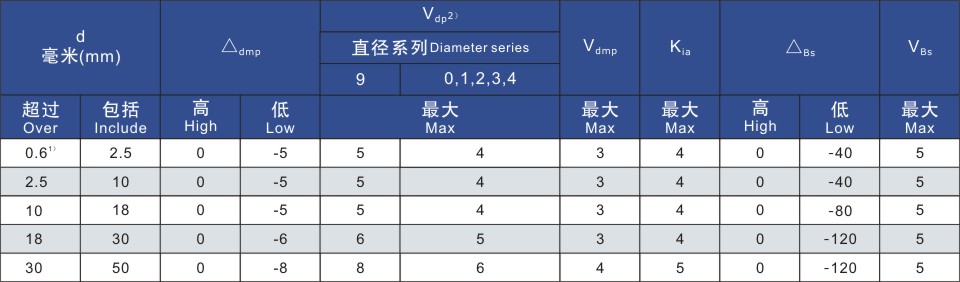

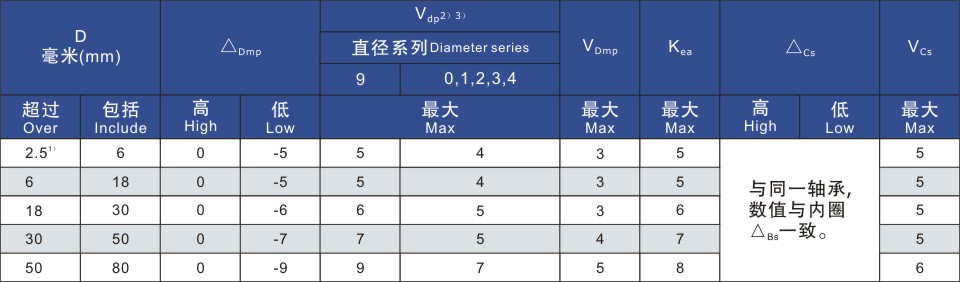

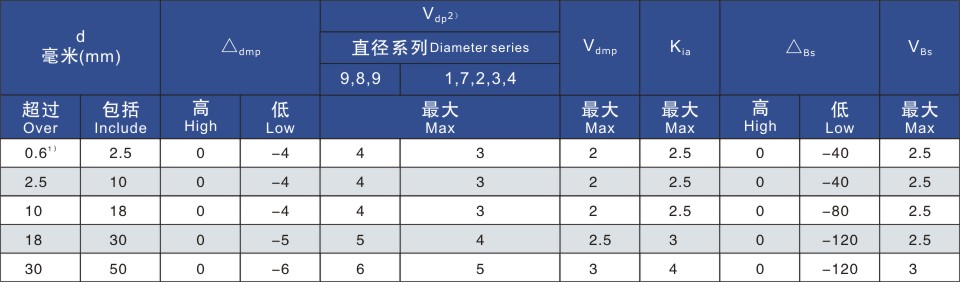

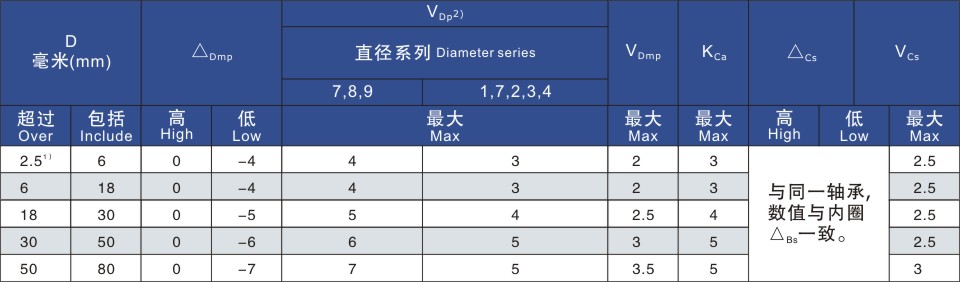

According to ISO international standard, bearing accuracy can be divided into P0, P6, P5 and P4 grades. The tolerance grade is according to Chinese national standard GB/ t307.1-2005 and iso492:2002 Setting. Please refer to table 3 for the tolerance grade comparison table

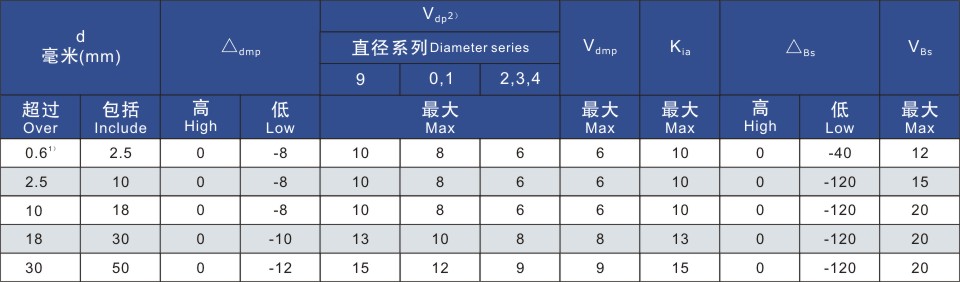

Note:

1) including 0.6.

2) the diameter series 7,8 have no specified value.

Note:

1) including 2.5.

2) the diameter series 7,8 have no specified value.

3) diameter series 9,0,1 has no specified value.

Note:

1) including 0.6.

2) the diameter series 7,8 have no specified value.

Note:

1) including 2.5.

2) the diameter series 7,8 have no specified value.

3) diameter series 9 has no specified value

Note:

1) including 0.6.

2) the diameter series 7,8 have no specified value.

Note:

1) including 2.5.

2) the diameter series 7,8 have no specified value.

3) diameter series 9 has no specified value

Note:

1) including 0.6.

2) the diameter series 7,8 have no specified value.

Note:

1) including 2.5.

2) the diameter series 7,8 have no specified value.

3) diameter series 9 has no specified value

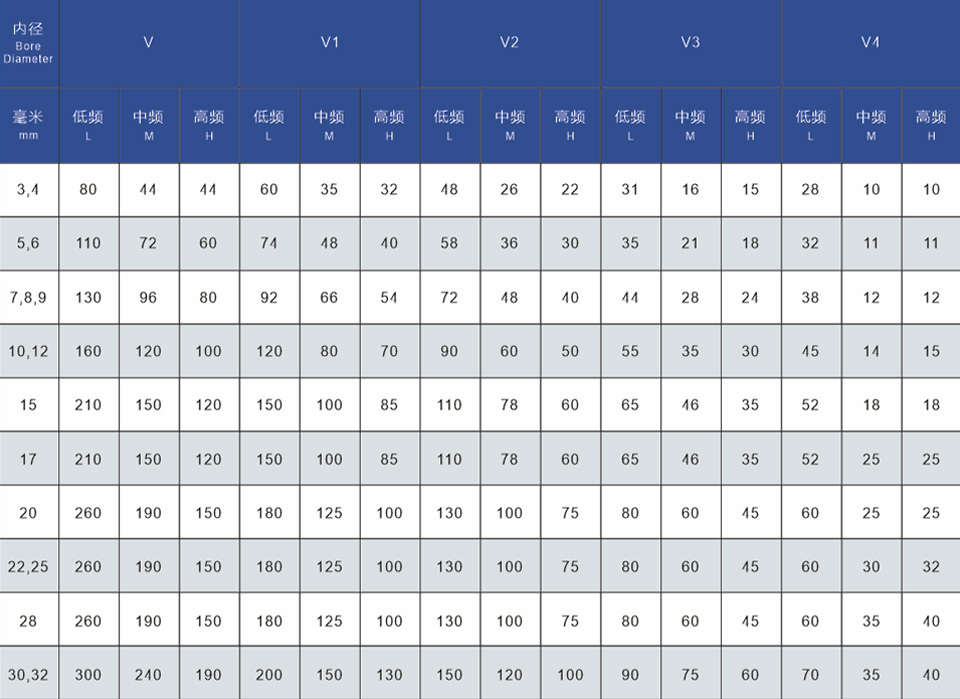

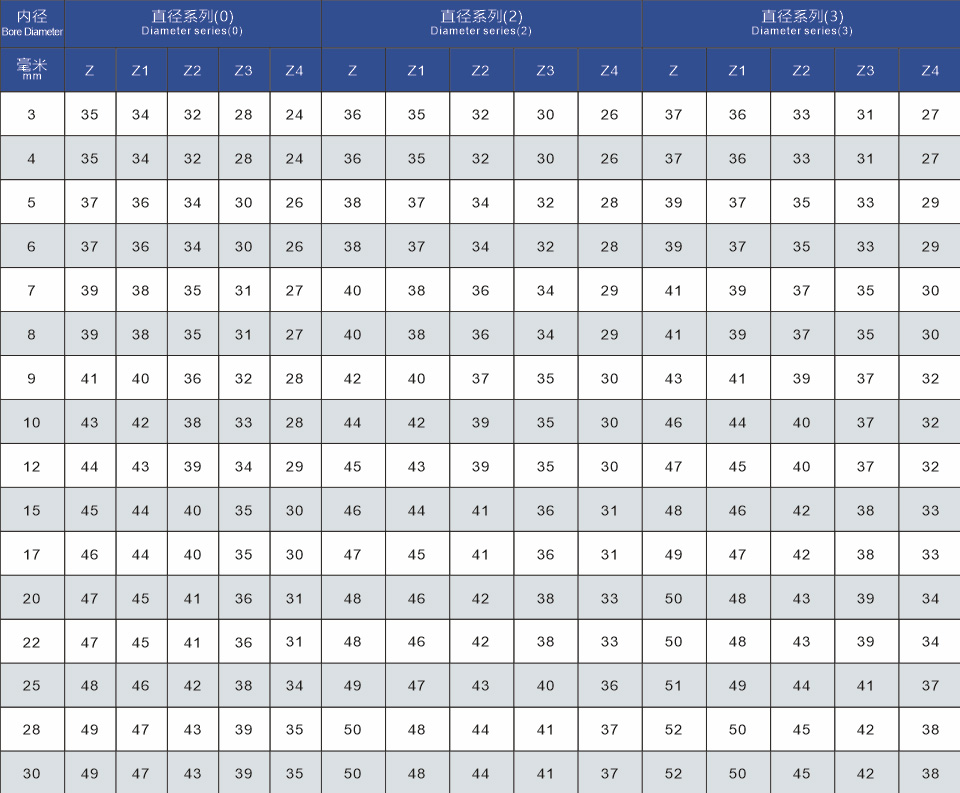

The vibration and noise levels of bearings can be divided into four levels: Z1, Z2, Z3 and Z4. It can be detected by s0910-1 instrument. Available upon special request Bvt-1 is detected and divided into V,V1,V2,V3 and V4. The specific data list is as follows. Customers should specify vibration and noise level requirements when placing orders.

Vibration tolerance data of single bearing:

Maximum vibration acceleration of a single bearing

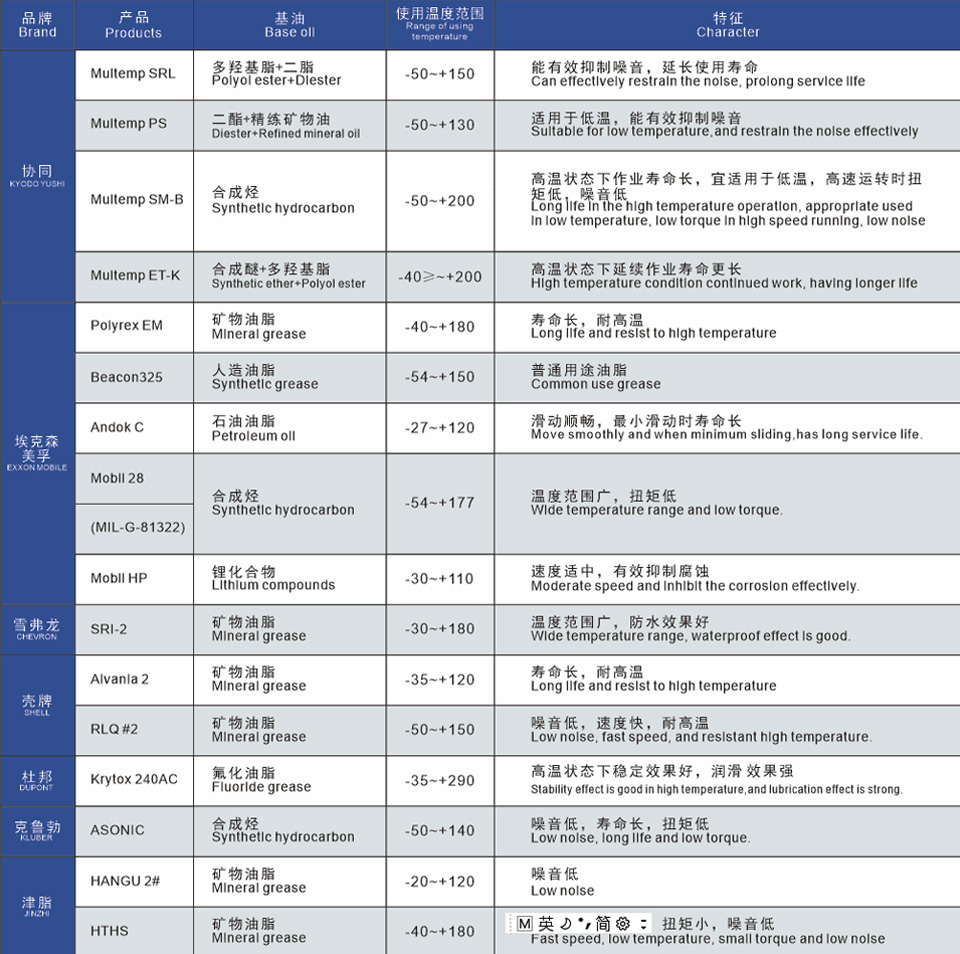

A variety of oils and fats are available for bearings. According to different working conditions and bearing operation conditions, we list the following commonly used grease for convenience Selected. In addition to the oils listed below, other oils may be added upon request.

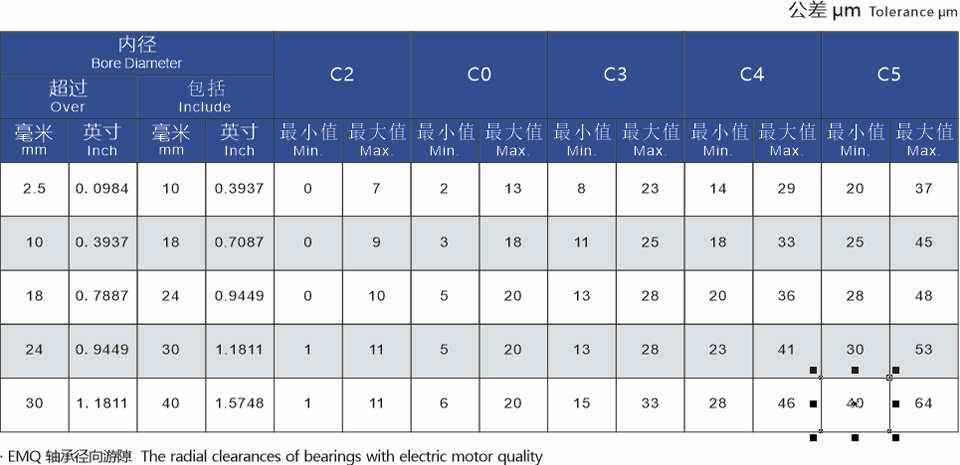

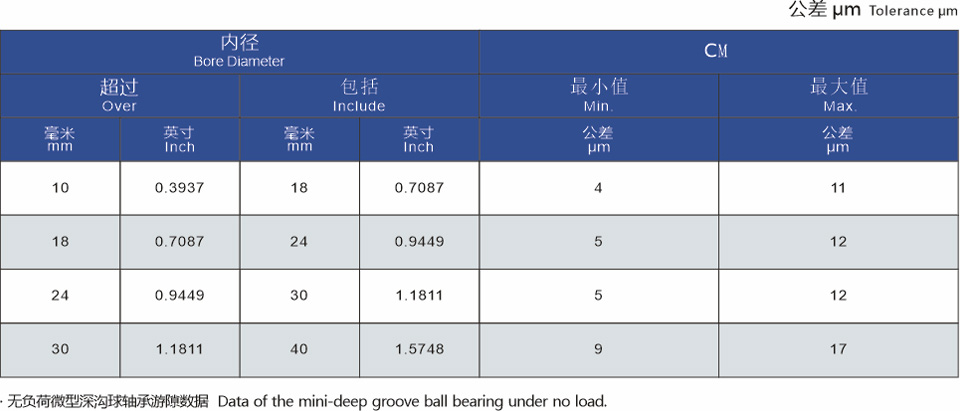

Internal clearance is determined so that appropriate clearance can be retained after bearing interference fitting is installed. The typical types of internal clearance of deep groove ball bearings are C2,C0,C3,C4 and C5. CM, MC clearance